Types of Abrasive Materials

March 07, 2023During the manufacturing process, metal parts can often accumulate impurities or develop imperfections, either naturally or due to processing steps. These flaws can complicate coating applications and other critical procedures, ultimately affecting the quality of the final product.

Abrasive blasting is a highly effective method for removing unwanted materials and preparing surfaces for further production stages. The technique involves using high-pressure water mixed with abrasive particles to blast away dirt, oil, grease, and chemicals, achieving the desired surface finish.

There are many types of abrasive media available, each with unique properties that make them suitable for different applications. Choosing the right one depends on factors like the material being treated, the required finish, and cost considerations.

Common Types of Abrasive Media

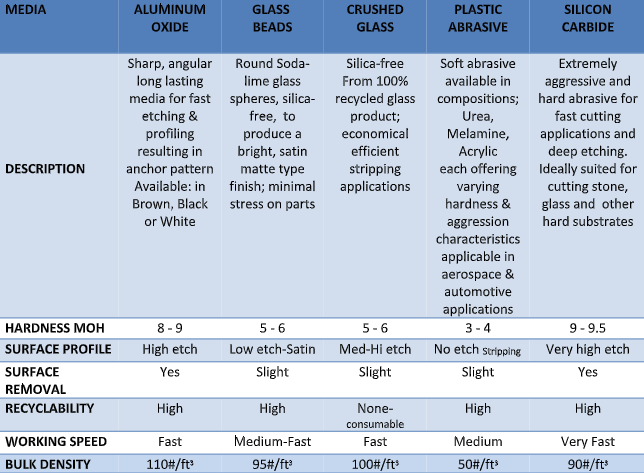

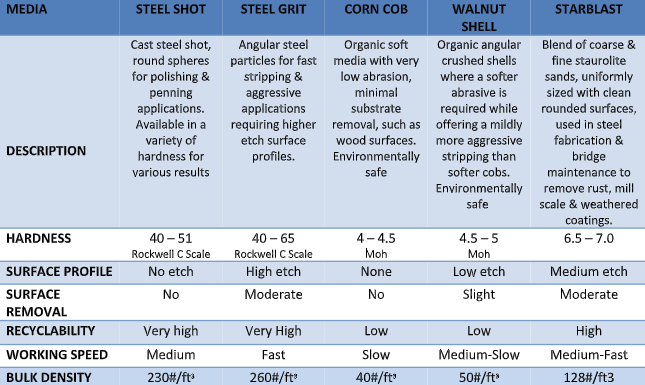

Below is an overview of some of the most commonly used abrasive media, along with their characteristics and typical applications:

- Glass Beads: Glass beads are less aggressive compared to materials like steel shot or silicon carbide. They are ideal for achieving a softer, brighter finish and are often used on stainless steel. Their recyclability makes them a sustainable choice.

- Aluminum Oxide: Known for its high hardness and strength, aluminum oxide is widely used in anti-slip surfaces, industrial blasting, and as a raw material in refractories. It is excellent for deep etching and surface preparation before painting or coating.

- Plastics: Plastic abrasives are made from crushed urea, polyester, or acrylic and come in various hardness levels and particle sizes. They are ideal for delicate applications such as mold cleaning, plastic part blasting, and when substrate removal is not allowed.

- Silicon Carbide: As the hardest abrasive available, silicon carbide is perfect for tough surface finishing tasks. It is used in lapping, polishing, glass etching, and heavy-duty blasting applications.

- Steel Shot & Grit: Steel abrasives are durable and highly recyclable, making them a cost-effective option. They are used for cleaning, texturing, and peening applications across various surfaces.

- Starblastâ„¢: This mined blend of staurolite sands has low silica content and is ideal for removing scale and corrosion from steel surfaces while minimizing dust buildup.

- Walnut Shells: A natural abrasive made from crushed walnut shells, it’s harder than other soft abrasives and is used for polishing softer materials like wood, plastic, and fiberglass without causing damage.

- Corn Cobs: Made from the dense woody rings of corn cobs, this softer abrasive is great for cleaning, deburring, and de-flashing in industries like jewelry, cutlery, and automotive.

Key Evaluation Criteria for Abrasive Media

When selecting the right abrasive, consider the following factors:

- Hardness: Measured on the Mohs scale, higher hardness means more aggressive surface interaction, which is important when working with softer substrates.

- Surface Profile: The size, shape, and density of the abrasive determine the profile it creates—ranging from no etch to high etch.

- Surface Removal: Understanding how much of the surface will be removed helps ensure the finish meets your project requirements.

- Recycling: Some abrasives can be reused, helping to reduce costs over time.

- Working Speed: Certain materials allow for faster blasting, improving efficiency.

- Bulk Density: This affects both the cleaning speed and the surface finish left behind.

Explore More About Abrasive Media Options

Finishing Systems offers a wide range of sandblast media options, available in different grit sizes and packaging to suit your specific needs. Our products are designed to deliver consistent quality and performance, helping you achieve the best results for your projects.

If you're unsure which abrasive media is right for your application, our team of experts is here to help. We provide guidance based on your industry, project goals, and budget.

Contact us today to learn more about our abrasive media solutions and get expert support tailored to your needs.

Heart Shaped Floral Foam,Heart Oasis Foam,Heart Shaped Oasis For Flowers,Heart Shaped Oasis Foam

SHANGHAI WELLONG IMPORT AND EXPORT CO., LTD , https://www.chinafloralfoam.com