High-Quality Water Fuel HHO Generator for Cars and Trucks

We are excited to introduce a revolutionary machine that acts like a money printer—HHO Generator Car Engine Carbon Cleaner.

This device is designed to clean carbon deposits from car engines using advanced technology. It’s one of the most innovative and fast-growing businesses globally, especially popular in countries like China, Mexico, USA, Canada, Singapore, India, and Malaysia.

HHO Carbon Cleaner MachineThe HHO Carbon Cleaner Machine removes carbon buildup from vehicle engines using catalytic principles. It features enhanced safety measures and utilizes a specially developed HHO Carbon Cleaner Agent. This cutting-edge technology ensures more effective results. HHO Carbon Cleaner Agent

This agent is non-corrosive, non-flammable, and completely safe. It not only improves the cleaning efficiency in the three-way catalyst and exhaust system but also protects engine components and extends the life of your vehicle's engine.

Benefits of Using HHO Carbon Cleaner 6.0:

- Restore power and performance

- Reduce engine vibration and noise

- Lower emissions

- Improve fuel efficiency

- Avoid costly repair bills

- Prolong engine lifespan

- Provide a smoother driving experience

2. The use of HHO agent significantly enhances the cleaning effect, making the results visible to the naked eye.

3. Thanks to the HHO agent, this cleaner can be used on all types of vehicles, including motorcycles, cars, trucks, buses, and trailers.

4. The HHO Carbon Cleaner 6.0 is a real money maker. Charge $80 per car, clean 6 cars a day, and with 22 working days, you could earn $10,560 in a month!

5. Kingkar offers the best after-sales service, including:

- One-year warranty, lifetime maintenance

- 30-day trial period

- 365-day replacement policy

- Professional team for market support, training, and maintenance

Why not reach out to us for a new business opportunity?

Send an inquiry now, and we’ll provide you with full details about this exciting business venture!

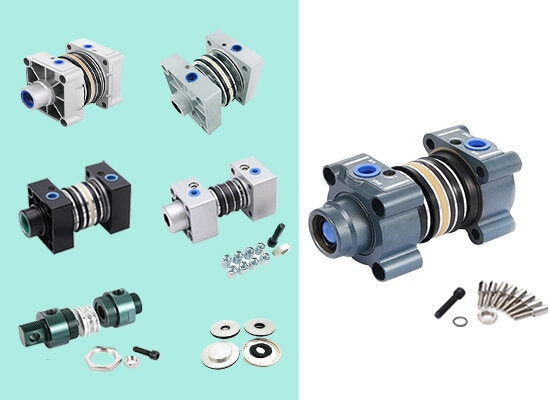

Cylinder assembly accessories include one front cover and one rear cover, one piston, two Y-type piston seals, one hard-wearing ring, one set of magnetic rings (some cylinders do not have magnetic rings), two cylinder seal O-rings, one piston rod sealing ring, one dustproof, two buffer caps, two buffer screws (with O-ring), one piston rod end thread, one piston fixing bolt, 8 fixing bolts, dustproof air inlet and outlet two caps, one piston rod end thread protection cover.Air Cylinder Tube.

Because the different application needs different strokes of air cylinders, for dealers and distributors, storing a large number of cylinders with fixed strokes will occupy a large amount of inventory funds.Pneumatic Cylinder Tube.

However, storing the Pneumatic Cylinder assembly parts can solve this problem very well. When requires different strokes and then temporarily assembling the cylinder accordingly.Air Cylinder Barrel.

Categories

Common cylinder assembly parts include DNC square cylinder series, ISO standard Metalwork series, SI Mickey Mouse type ISO 15552 cylinder series, SC and SU AirTac standard cylinder series, SDA compact cylinder series, and DSN, MA, MAL mini air cylinder series, etc. .

Matters needing attention when assembling the cylinder

For non-professional cylinder manufacturers, we do not recommend self-assembly to avoid problems caused by incorrectly assembling cylinders.

The following points need to be paid attention to when assembling an air cylinder by yourself:

â—† The inner edge of a pneumatic cylinder needs to be chamfered to facilitate the entry of the piston and sealing ring into the cylinder tube.

â—† Before assembling the piston and cylinder, lubricating grease must be applied to the inner wall of the cylinder to reduce the friction between the sealing ring and the inner wall of the air cylinder.Pneumatic Cylinder Barrel.

â—† The edge of the piston rod end also needs to be chamfered to reduce damage to dust and buffer seals.Pneumatic Cylinder.

â—† Because the end of the piston rod has external threads, special attention should be paid when assembling the piston rod and the front end cover. It is necessary to use the end of the piston rod without threads to pass through the gasket. Otherwise, the inner wall of the gasket is easily cut by the threads and resulting in an air leakage.

â—† For the installation of the tie rod cylinder, it is also necessary to pay attention to the position of the tie rod thread, so that there is enough thread space in the fixing bolts of the front and rear end covers to install the cylinder accessories such as CA, CB mounting brackets, FA/FB flange brackets.Cylinder Tube.

Pneumatic Cylinder Kits,Air Cylinder Kits,Pneumatic Air Cylinder Kits,Aluminum Cylinder Kits

Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com