Bridges are crucial for transportation and economic growth, but they often face challenges due to heavy usage and aging infrastructure. This leads to frequent and costly repairs.

In the U.S., over a third of bridges require significant repair or replacement, while more than 3,200 in the UK are in poor condition. As the need for faster and more efficient inspections increases, drones are emerging as a game-changing solution.

Unlike traditional methods that involve lane closures and manual checks, drones can access hard-to-reach areas without disrupting traffic. They quickly gather detailed data, enabling advanced inspections for corrosion, structural weaknesses, and even thickness measurements.

This article will explore the benefits of using drones in bridge inspection, the best tools for the job, and how drones are transforming maintenance in the face of aging infrastructure.

Benefits of Using a Drone for Bridge Inspection

Drones offer a more efficient, safe, and accurate approach to bridge inspections compared to traditional methods.

Enhanced Accessibility and Safety

Drones are game changers when it comes to accessing hard-to-reach areas on bridges. Bridges are often complex structures with tall towers, narrow beams, and undersides that are challenging or dangerous to inspect manually.

Traditional methods require workers to physically access these areas, often with scaffolding, cranes, or ropes, which can be risky and time-consuming.

With drones, inspectors can fly close to these difficult spots—like the underside of a suspension bridge or over water—without needing to put anyone in harm’s way. This drastically reduces the risk of falls or accidents.

Improved Efficiency and Cost-Effectiveness

Drone inspections are significantly faster and cheaper than traditional methods. A typical bridge inspection can take days or even weeks, especially when scaffolding or heavy machinery is involved. Drones, however, can complete the same task in a matter of hours. In many cases, drones can cut inspection times by up to 75%.

Cost savings are another big plus. Traditional bridge inspections can cost anywhere from $4,500 to $10,000 per bridge, depending on the size and complexity of the structure.

Drones eliminate the need for much of the expensive equipment and labor, bringing down costs significantly. Some reports indicate that drones can save up to 40% on inspection costs, meaning agencies can redirect those funds to other maintenance tasks.

Enhanced Data Collection and Analysis

Drones significantly enhance data collection for bridge inspections through advanced imaging technologies. High-resolution cameras capture detailed images of bridges, allowing inspectors to detect even the smallest defects, such as cracks and corrosion, that might be missed by manual inspection.

Thermal imaging provides an additional layer of analysis, detecting temperature anomalies that indicate hidden structural issues, such as water ingress or material degradation.

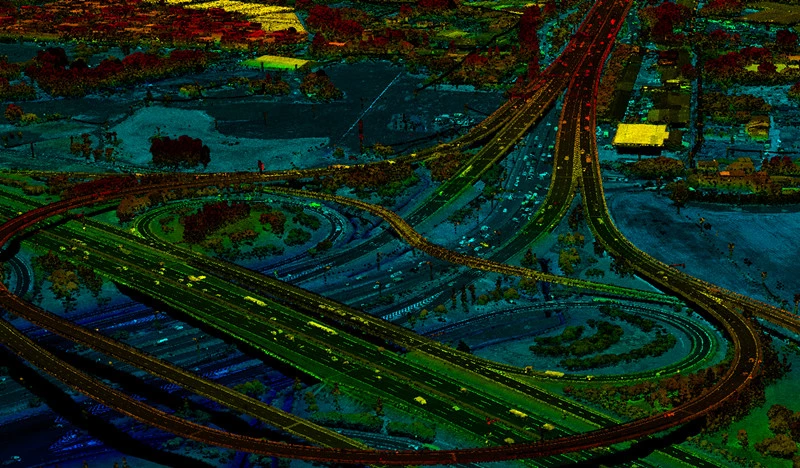

Drones also enable the creation of accurate 3D models using LiDAR technology. These models allow engineers to analyze a bridge from multiple angles, taking precise measurements and tracking changes over time.

Improved Accuracy and Precision

Manual inspections are limited by human error and the physical ability of workers to access all areas of the structure. In contrast, drones can fly to within inches of a bridge’s surface, capturing detailed images and generating 3D models with extreme precision.

For example, LiDAR-equipped drones can detect deviations as small as 1 cm in structural components, making it easier to identify early signs of deterioration, such as surface cracks or material displacement.

Real-Time Monitoring and Early Detection

By conducting regular inspections, drones can identify potential problems before they escalate into serious safety hazards. This proactive approach allows maintenance teams to address minor repairs quickly, saving time and money in the long run.

In addition to regular inspections, many advanced drones are equipped with sensors that enable real-time monitoring of a bridge's health. These sensors can track vital parameters such as vibrations, temperature changes, and structural movement.

For instance, if a drone detects unusual vibrations or shifts in a bridge during high traffic or severe weather, it can send immediate alerts to engineers. This allows for quick assessments and interventions, preventing small issues from developing into major problems.

The PH-20's gimbal camera allows for stable, high-quality video and images, making it perfect for monitoring traffic flow and conducting safety inspections on bridges.

Best Drones for Bridge Inspection

When selecting a drone for bridge inspection, it's essential to consider factors such as payload capacity, flight endurance, range, and camera quality.

JOUAV PH-20

| Pros | Cons |

|

|

The JOUAV PH-20 is a robust drone designed for heavy payload operations, capable of carrying up to 10 kg of sensors, including high-resolution cameras and LiDAR systems. Its impressive flight time of up to 75 minutes is particularly beneficial for inspecting large bridges, as it minimizes battery changes and maximizes coverage per flight.

Equipped with a high-resolution thermal camera, the PH-20 allows inspectors to detect heat anomalies indicative of structural issues like fatigue or insulation failures. The drone incorporates AI technology for automatic defect detection, enhancing inspection efficiency. Additionally, its RTK (Real-Time Kinematic) positioning system ensures centimeter-level accuracy, critical for assessing bridge integrity.

The PH-20 is designed for durability, boasting an IP55 rating for water and dust resistance, which enables inspections in challenging weather conditions. Its integrated obstacle avoidance system further enhances safety by allowing navigation around complex structures. Overall, the JOUAV PH-20 is an excellent choice for comprehensive and reliable bridge inspections.

DJI Matrice 300 RTK

| Pros | Cons |

|

|

The Matrice 300 RTK's 55-minute flight time allows it to complete most bridge inspections in one go, minimizing the need for battery changes, which is especially useful for long or remote bridges.

Equipped with the H20 hybrid camera, which includes a 20MP zoom, 12MP wide-angle, thermal camera, and laser rangefinder, it captures detailed visual and thermal data, making it easier to detect surface and internal structural issues.

Its RTK system provides real-time GPS accuracy, eliminating the need for ground control points (GCPs) and enabling efficient data collection, especially for bridges where GCPs are hard to place.

AI-powered spot-checks automate routine inspections, ensuring consistency in tracking corrosion, cracks, or stress over time, and enhancing long-term maintenance planning. With an upward gimbal, the Matrice 300 RTK allows inspectors to easily view hard-to-reach areas like the underside of bridges, reducing the need for scaffolding.

Its 15km transmission range ensures safe operation in challenging environments, like remote or obstructed bridge sites. The drone’s durability, operating in temperatures from -20°C to +50°C, ensures reliable performance in extreme weather, allowing inspections to stay on schedule.

Autel Evo 2 Pro RTK

| Pros | Cons |

|

|

The Autel Evo 2 Pro RTK is a more affordable yet powerful option for bridge inspections. It offers a flight time of approximately 40 minutes and supports high-resolution imaging with its 6K video capabilities. This drone is particularly appealing for teams looking for quality data without breaking the bank.

The Evo 2 Pro RTK is equipped with both RTK and PPK (Post-Processed Kinematic) systems, enhancing the accuracy of the data collected during inspections. This precision is especially important when assessing structural integrity and pinpointing any areas of concern. The drone's obstacle avoidance technology further adds to its safety, allowing it to navigate around complex bridge structures without risk.

Thermal imaging capabilities are another key feature of the Evo 2 Pro RTK. This function enables inspectors to detect temperature variations that could indicate underlying structural issues, making it a valuable tool for comprehensive assessments.

Skydio 2+

| Pros | Cons |

|

|

The Skydio 2+ distinguishes itself through its advanced autonomous flying capabilities. It is designed to navigate complex environments on its own, which can be particularly beneficial when inspecting intricate bridge designs. Its ability to fly autonomously reduces the need for skilled pilots, making it accessible for a broader range of users.

This drone features a 4K HDR camera that captures high-quality images and videos, providing inspectors with the detailed visuals necessary for thorough assessments. Although it has a shorter flight time of around 27 minutes, its autonomous capabilities allow it to maximize the coverage of each flight, making it efficient for bridge inspections.

The Skydio 2+ is ideal for situations where safety is a concern, as its AI technology allows it to avoid obstacles in real-time. This makes it especially useful for inspecting hard-to-reach areas where traditional methods might pose risks to personnel.

DJI Mavic 3 Enterprise Thermal

| Pros | Cons |

|

|

The DJI Mavic 3 Enterprise Thermal is a compact and versatile drone suitable for a variety of inspection tasks, including bridges. With a flight time of up to 45 minutes, it strikes a balance between performance and portability. It offers multiple camera options, including a thermal sensor and a high-resolution visual camera, enabling comprehensive data collection during inspections.

The Mavic 3 Enterprise Thermal is particularly advantageous for teams that require a quick deployment. Its lightweight design makes it easy to transport, and it can be quickly set up for inspections, which is especially valuable in emergency situations. The user-friendly interface allows for seamless operation, even for those with limited experience in drone piloting.

Multi Ribbed Poly V Belts,Multi Ribbed Poly V-belt,Multi Poly V Belt,Multi Ribbed Poly Belt

Zhoushan Aosheng Auto Transmission Belt Manufacturing Co., Ltd. , https://www.aoshengbelt.com