Table of contents

- What is Sheet Metal Gauge Chart

- Aluminum Gauge Chart

- Popular Sheet Metal Materials

- Sheet Metal Applications

- Mild Steel Gauge Chart

- Galvanized Steel Gauge Chart

- Stainless Steel Gauge Chart

- Copper Gauge Chart

- Sheet Metal Fabrication

- Steel Sheet Metal Tolerances

- Stainless Steel Sheet Metal Gauge Chart Thickness

- Sheet Metal Surface Finishes

- Brass Gauge Chart

- Sheet Metal Weldings

- Stainless Steel Sheet Weight

- How are Sheet Metal Gauges Used?

- Sheet Metal Advantages and Disadvantages

What is a Sheet Metal Gauge Chart?

Sheet metal gauges are used to measure the thickness of metal sheets. These numbers represent the relationship between the weight and thickness of the sheet, typically in square feet. A higher gauge number means a thinner sheet, while a lower gauge number indicates a thicker one. This system helps engineers and manufacturers choose the right material for their specific applications.

Understanding Aluminum Gauge Charts

Knowing the exact thickness of aluminum is crucial for welding and machinery setup. Different parts may require varying thicknesses for strength and durability. Too thick or too heavy can increase production and shipping costs. The aluminum gauge chart provides precise measurements to help you select the most suitable thickness for your project.

Looking for the Best Quality Sheet in Various Sizes? Check Below for the Sheet Metal Gauge Chart in mm and Inches

Aluminum Gauge Chart

| Gauge No. | 7 | 8 | 9 | 10 | 11 | 12 | 14 | 16 |

|---|---|---|---|---|---|---|---|---|

| MM | 3.665 | 3.264 | 2.906 | 2.588 | 2.305 | 2.053 | 1.628 | 1.291 |

| Inches | 0.1443 | 0.1285 | 0.1144 | 0.1019 | 0.09074 | 0.08081 | 0.06408 | 0.05082 |

| Gauge No. | 18 | 20 | 22 | 24 | 26 | 28 | 30 | – |

| MM | 1.024 | 0.812 | 0.644 | 0.511 | 0.405 | 0.321 | 0.255 | – |

| Inches | 0.0403 | 0.03196 | 0.02535 | 0.0201 | 0.01594 | 0.01264 | 0.01003 | – |

Popular Sheet Metal Materials

| Stainless steel | Pre-plated steel | Cold rolled steel | Copper/Brass | Aluminum | |

|---|---|---|---|---|---|

| 400 series | 300 series | hot-dip galvanized steel | used to smooth the finish hot rolled steel | electrolytically tough pitch (ETP) | Grade 1100: low strength |

| Grade 410: less corrosion resistance, heat treatable | Grade 316: corrosion-resistant, maintains strength at high temperatures | Â | available in 1018, 1008 alloys | C110 or C101 | weldable and ductile |

| Grade 430: used in applications where corrosion resistance is not required | Grade 304: widely used, less corrosion-resistant | Â | Â | cartridge brass (alternative) | Grade 3003:Stronger, corrosion-resistant |

| Â | good formability and weldability | Â | Â | Â | Â |

Sheet Metal Applications

- Architectural

- Structural components

- Housings

- Enclosures

- Manufacturing

- Cabinets

- Construction

- Automation

The Gauge Value Varies by Material

The gauge value represents the thickness of the sheet, measured in inches or millimeters. Higher gauge numbers mean thinner sheets. Non-ferrous metals like copper and aluminum use different standards, often based on ounces per square foot. Understanding these differences is essential for accurate material selection.

Find Below Standard Gauges of Sheet Metal Chart for Different Materials

Mild Steel Gauge Chart

| Gauge no. | 7 | 8 | 9 | 10 | 11 | 12 | 14 |

|---|---|---|---|---|---|---|---|

| MM | 4.554 | 4.175 | 3.797 | 3.416 | 3.038 | 2.656 | 1.897 |

| Inches | 0.1793 | 0.1644 | 0.1495 | 0.1345 | 0.1196 | 0.1046 | 0.0747 |

| Gauge no. | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| MM | 1.518 | 1.214 | 0.911 | 0.759 | 0.607 | 0.454 | 0.378 |

| Inches | 0.0598 | 0.0478 | 0.0359 | 0.0299 | 0.0239 | 0.0179 | 0.0149 |

Galvanized Steel Gauge Chart

| Gauge no. | 8 | 9 | 10 | 11 | 12 | 14 | 16 |

|---|---|---|---|---|---|---|---|

| MM | 4.269 | 3.891 | 3.51 | 3.1318 | 2.753 | 1.9939 | 1.6129 |

| Inches | 0.1681 | 0.1532 | 0.1382 | 0.1233 | 0.1084 | 0.0785 | 0.0635 |

| Gauge no. | 18 | 20 | 22 | 24 | 26 | 28 | 30 |

| MM | 1.31 | 1.005 | 0.853 | 0.701 | 0.551 | 0.474 | 0.398 |

| Inches | 0.0516 | 0.0396 | 0.0336 | 0.0276 | 0.0217 | 0.0187 | 0.0157 |

Stainless Steel Gauge Chart

| Gauge No | 8 | 9 | 10 | 11 | 12 | 14 | 16 |

|---|---|---|---|---|---|---|---|

| MM | 4.365 | 3.968 | 3.571 | 3.175 | 2.778 | 1.984 | 1.587 |

| Inches | 0.17187 | 0.15625 | 0.14062 | 0.125 | 0.10937 | 0.07812 | 0.0625 |

| Gauge No | 18 | 20 | 22 | 24 | 26 | 28 | 30 |

| MM | 1.27 | 0.9525 | 0.7937 | 0.635 | 0.476 | 0.396 | 0.3175 |

| Inches | 0.05 | 0.0375 | 0.03125 | 0.025 | 0.01875 | 0.01562 | 0.0125 |

Copper Gauge Chart

| Gauge No. | 7 | 8 | 9 | 10 | 11 | 12 | 14 | 16 |

|---|---|---|---|---|---|---|---|---|

| MM | 4.572 | 4.191 | 3.759 | 3.404 | 3.048 | 2.769 | 2.108 | 1.651 |

| Inches | 0.18 | 0.165 | 0.148 | 0.134 | 0.12 | 0.109 | 0.083 | 0.065 |

| Gauge No. | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

| MM | 1.245 | 0.889 | 0.711 | 0.559 | 0.457 | 0.356 | 0.305 | |

| Inches | 0.049 | 0.035 | 0.028 | 0.022 | 0.018 | 0.014 | 0.012 |

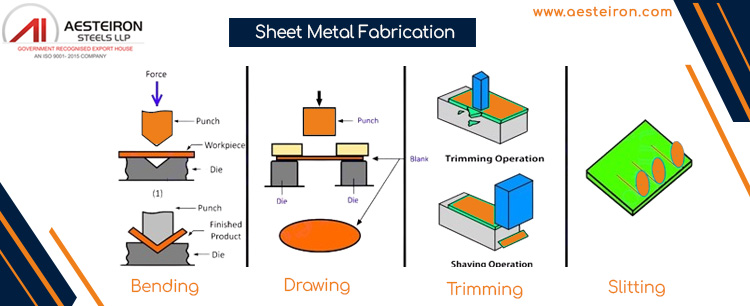

Sheet Metal Fabrication

| Bending | Cutting | Punching | Forming |

|---|---|---|---|

Created bend line and then applying force to achieve the desired angle |

choice of method depends on the thickness, material type and required precision |

Done by punching press or a CNC machine |

shaping the metal into desired forms

|

| Welding | Finishing | Inspection | Â |

Ensures that parts are securely attached |

protect against corrosion |

|

|

Size Range of sheet metal gauge chart is 0/7 SWG to 50 SWG

Steel Sheet Metal Tolerances

| Gauge | 10 | 11 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal [in] | 0.1345 | 0.1196 | 0.1046 | 0.0747 | 0.0598 | 0.0478 | 0.0359 | 0.0299 | 0.0239 | 0.0179 | 0.0149 | |

| Max | Size [in] | 0.1405 | 0.1256 | 0.1106 | 0.0797 | 0.0648 | 0.0518 | 0.0389 | 0.0329 | 0.0269 | 0.0199 | 0.0169 |

| Min | Size [in] | 0.1285 | 0.1136 | 0.0986 | 0.0697 | 0.0548 | 0.0438 | 0.0329 | 0.0269 | 0.0209 | 0.0159 | 0.0129 |

Stainless Steel Sheet Metal Gauge Chart Thickness

| Gauge | 12 | 11 | 24 | 16 |

|---|---|---|---|---|

| Thickness | 0.109" | 2.78mm | 0.120" | 3.05 mm | 0.025" | 0.64 mm | 0.063" | 1.59mm |

| Thickness Tolerance | ± 0.009 | ± 0.23mm | ± 0.005 | ± 0.003 | ± 0.08mm | ± 0.006 | ± 0.15mm |

| Gauge | 14 | 20 | 18 | 22 |

| Thickness | 0.078" | 1.98mm | 0.038" | 0.95mm | 0.050" | 1.27mm | 0.031" | 0.79 mm |

| Thickness Tolerance | ± 0.007 | ± 0.18mm | ± 0.004 | ± 0.10mm | ± 0.005 | ± 0.13mm | ± 0.004 | ± 0.10mm |

Sheet Metal Surface Finishes

- Annealing

- Galvanised

- Tinning

- Anodising

- Tempering

Refer Brass gauge thickness in MM

Brass thickness plays a key role in manufacturing. If it's too thick, it becomes hard to cut or shape. If it's too thin, it might bend easily or fail. It also affects the product's strength and longevity, as well as the project cost. Thinner brass can be damaged by high heat, so welders need to manage heat exposure carefully.

Brass Gauge Chart

| Gauge No. | 7 | 8 | 9 | 10 | 11 | 12 | 14 | 16 |

|---|---|---|---|---|---|---|---|---|

| MM | 3.665 | 3.264 | 2.906 | 2.588 | 2.305 | 2.053 | 1.628 | 1.291 |

| Inches | 0.1443 | 0.1285 | 0.1144 | 0.1019 | 0.09074 | 0.08081 | 0.06408 | 0.05082 |

| Gauge No. | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

| MM | 1.024 | 0.812 | 0.644 | 0.511 | 0.405 | 0.321 | 0.255 | |

| Inches | 0.0403 | 0.03196 | 0.02535 | 0.0201 | 0.01594 | 0.01264 | 0.01003 |

Sheet Metal Weldings

MIG Welding

TIG Welding

Laser Welding

Stick Welding

GAS Welding

Plasma Arc welding

Gauge Sizes are Depends on a Weight of Steel Which is 41.82 Pounds Per sq foot per inch of Thickness

This standard gauge ensures uniformity in sheet thickness, which directly impacts the toughness, longevity, and performance of the final product. It allows for precise design and manufacturing processes, helping to avoid unnecessary material usage and reduce costs.

Stainless Steel Sheet Weight

| Weight Per Stainless Steel Sheet | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight KG/M2 | 1.44 | 1.6 | 1.76 | 1.92 | 2.16 | 2.24 | 2.56 | 3.04 | 3.52 | 4 | 4.48 | 5.04 | 6 | 7.04 | 8 | 9.04 | 10 | 72 | 12 | |

| Thickness (mm) | 0.18 | 0.2 | 0.22 | 0.24 | 0.27 | 0.28 | 0.32 | 0.38 | 0.44 | 0.5 | 0.56 | 0.63 | 0.75 | 0.88 | 1 | .1.13 | 1.25 | 1.38 | 1.5 | |

| Size(mm) | 2500 X 1250 | – | – | – | – | – | – | – | – | 11 | 12.5 | 14 | 15.75 | 18.75 | 22 | 25 | 28.25 | 31.25 | 34.5 | 37.5 |

| 2000 X 1000 | 2.88 | 3.2 | 3.52 | 3.84 | 4.32 | 4.48 | 5.12 | 6.08 | 7.04 | 8 | 8.96 | 10.08 | 12 | 14.08 | 16 | 18.08 | 20 | 22.03 | 24 | |

| 3000 X 1500 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 36 | 40 | 45 | 50 | 54 | |

| Weight KG/M2 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | 64 | |

| Thickness (mm) | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | |

| Size(mm) | 2500 X 1250 | 43.75 | 50 | 56.25 | 62.5 | 68.75 | 75 | 81.25 | 87.5 | 93.75 | 100 | 106.25 | 112.5 | 125 | 137.5 | 150 | 162.5 | 175 | 187.5 | 200 |

| 2000 X 1000 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | 64 | 68 | 72 | 80 | 88 | 96 | 104 | 112 | 120 | 128 | |

| 3000 X 1500 | 63 | 72 | 81 | 90 | 99 | 108 | 117 | 126 | 135 | 144 | 153 | 162 | 180 | 198 | 216 | 234 | 252 Direct Fired Absorption Chiller If you want to know more about the products, please click the product details to view parameters, models, pictures, prices and other information. Direct Fired Lithium Bromide Absorption Chiller,Homemade Absorption Chiller,Direct-Fired Absorption Chiller,Gas Fired Absorption Chiller EBARA REFRIGERATION EQUIPMENT & SYSTEMS (CHINA) CO., LTD. , https://www.ebara-hvac.com | |||