Magnetic Particle Inspections: A Comprehensive Guide

Magnetic particle inspection (MPI) is a non-destructive testing method used to detect surface and near-surface defects in ferromagnetic materials. The process involves magnetizing the material and applying magnetic particles, which are attracted to areas where the magnetic field leaks due to the presence of flaws.

This technique is widely used in industries such as aerospace, automotive, and manufacturing for quality control and safety assessments. It can identify various types of defects, including cracks, porosity, cold laps, and incomplete fusion in welds.

Also known as magnetic particle testing (MT), this method is valued for its simplicity, speed, and cost-effectiveness. However, it is limited to ferromagnetic materials like iron, steel, cobalt, and nickel.

In this guide, we will use the terms "magnetic particle inspection" and "magnetic particle testing" interchangeably, as they refer to the same procedure.

The basic principle of MPI is straightforward: when a material is magnetized, any surface or near-surface defect disrupts the magnetic field, creating a leakage field. Magnetic particles, either dry or in a liquid suspension, are then applied to the surface. These particles gather around the leakage field, making the defect visible to inspectors.

One of the key advantages of MPI is that it provides immediate results, allowing inspectors to quickly identify and address potential issues. It is also relatively easy to perform, requiring minimal preparation compared to other NDT methods.

However, there are some limitations. For instance, the material must be ferromagnetic, and the inspection is only effective for shallow defects. Additionally, after testing, the material often needs to be demagnetized, which can be a time-consuming process.

[NDT magnetic particle testing is just one of the non-destructive testing methods that inspectors use. Learn more about NDT and the other methods used in this guide.]

What Is Magnetic Particle Testing?

Magnetic particle testing begins with magnetizing the object under inspection. If no defects are present, the magnetic field flows smoothly through the material. However, if a defect exists, the magnetic field is disrupted, creating a flux leakage field at the location of the flaw.

Once the material is magnetized, inspectors apply magnetic particles to the surface. These particles are drawn to the leakage field, forming a visible indication that highlights the defect. The particles may be dry or suspended in a liquid, and they are often colored or fluorescent to improve visibility.

The History of Magnetic Particle Testing

The concept of using magnetism to detect material flaws dates back to 1868, when cannon barrels were tested by magnetizing them and using a compass to detect disruptions in the magnetic field. In the 1920s, inventor William Hoke discovered that metallic shavings could reveal defects on magnetized surfaces, laying the foundation for modern MPI.

By the 1930s, the railroad industry adopted this method for inspecting steel components, and it became a standard practice in many industries. Today, the principles of MPI remain largely unchanged, though the tools and techniques have evolved significantly.

The Pros and Cons of Magnetic Particle Inspection

MPI is a popular choice for many inspections due to its speed, affordability, and ease of use. It can detect both surface and subsurface flaws, and it requires minimal pre-cleaning of the material.

However, it has some drawbacks. It is only applicable to ferromagnetic materials, and it cannot detect deep-seated defects. Additionally, the test may require removing paint or coatings if they are too thick, and the material must be demagnetized afterward.

Pros

- Fast and efficient

- Cost-effective

- Easy to interpret results

- Can detect very fine cracks

- Flexible for irregular shapes

- Minimal preparation required

- Available in both dry and wet forms

Cons

- Limited to ferromagnetic materials

- Only detects shallow defects

- Requires demagnetization

- Paint must be removed in some cases

- May miss defects not aligned with the magnetic field

Magnetic Particle Testing Techniques

MPI can be performed using either dry or wet methods. Dry magnetic particle testing (DMPT) involves applying dry particles directly to the surface, while wet magnetic particle testing (WMPT) uses a liquid suspension of particles.

Both methods can use fluorescent or non-fluorescent particles, depending on the lighting conditions and the inspector’s preference. This flexibility allows for optimal visibility of defects in different environments.

Two-Step Overview

The process typically involves two main steps:

- Magnetize the object: Apply a magnetic current to the material. Any existing defects will create a secondary magnetic field, or flux leakage field.

- Apply magnetic particles: Spread the particles over the surface. They will be attracted to the leakage fields, making the defects visible.

While the basic process is simple, the actual execution depends on several factors, including the type of material, the size of the object, and the nature of the defects being sought.

Common on-site techniques include the use of electromagnetic yokes, current flow probes, permanent magnets, flexible coils, and adjacent cables.

Magnetization Considerations

Magnetization is a critical step in MPI, and the method used can affect the accuracy of the results. There are several techniques for magnetizing materials, each suited to different applications.

Ways to Magnetize the Material

The five most commonly used magnetization techniques include:

- Longitudinal magnetization

- Multidirectional magnetization

- Yoke technique

- Prod technique

- Circular magnetization

These methods are recognized by standards organizations such as ASME and are widely used in industrial settings.

Perpendicular Application

To ensure accurate detection, the magnetic lines of force should be applied perpendicular to the direction of the electric current. This is important because a defect will only disrupt the magnetic field if it is oriented correctly relative to the flux.

Therefore, inspectors often conduct the test twice—once in one direction and once in a perpendicular direction—to cover all possible defect orientations.

Direct vs. Indirect Magnetization

Direct magnetization involves passing an electric current directly through the material, while indirect magnetization creates a magnetic field from an external source. Each approach has its own advantages and is suitable for different inspection scenarios.

Electrical Current Considerations

The choice of electrical current depends on the inspection requirements. Alternating current (AC) is ideal for surface flaws, while direct current (DC) can penetrate deeper into the material, making it suitable for detecting subsurface defects.

Full-wave DC and half-wave DC are variations of DC that offer different levels of penetration and are used based on the specific needs of the inspection.

Magnetic Particle Inspection Equipment

A variety of equipment is used in magnetic particle inspection, including magnetic benches, power packs, magnetic yokes, enclosures, and demagnetizers. Each tool serves a specific purpose in the inspection process.

Magnetic Wet Benches

Magnetic wet benches are used to generate circular and longitudinal magnetic fields for testing. They are particularly useful for large or complex parts.

A magnetic wet bench | Credit: Magnaflux

Power Packs / Electromagnetic Current Generators

Power packs provide a quick and efficient way to generate the necessary magnetic current for inspection. They are portable and widely used in field applications.

A portable power pack | Credit: Magnaflux

A portable power pack | Credit: Magnaflux

Magnetic Yokes

Magnetic yokes are used to generate a localized magnetic field for inspection. They are especially useful for on-site testing of large structures.

An electromagnetic AC/DC yoke | Credit: Magnaflux

An electromagnetic AC/DC yoke | Credit: Magnaflux

Enclosures, Hoods, and Curtains

Enclosures, hoods, and curtains are used to create the proper lighting conditions for inspecting fluorescent particles. They help reduce ambient light and improve visibility during the inspection process.

An enclosure | Credit: Magnaflux

An enclosure | Credit: Magnaflux

Demagnetizers

Demagnetizers are used to remove residual magnetism from the inspected material after the test is complete. This is important to prevent interference with other processes or equipment.

A table-top demagnetizer | Credit: Magnaflux

Magnetic Particle Inspection Standards and Codes

Many industries require adherence to specific standards when conducting magnetic particle inspections. These standards ensure consistency, accuracy, and safety in the testing process.

Some of the internationally recognized standards include ASTM, ISO, and CEN guidelines, which outline procedures, equipment requirements, and acceptance criteria for MPI.

ASTM (American Society of Testing and Materials)

- ASTM E1444/E1444M: Standard Practice for Magnetic Particle Testing

- ASTM A275/A275M: Test Method for Magnetic Particle Examination of Steel Forgings

- ASTM A456: Specification for Magnetic Particle Inspection of Large Crankshaft Forgings

- ASTM E543: Practice Standard Specification for Evaluating Agencies that Performing Nondestructive Testing

- ASTM E709: Guide for Magnetic Particle Testing Examination

- ASTM E1316: Terminology for Nondestructive Examinations

ISO (International Standards Organization)

- ISO 3059: Non-destructive testing - Penetrant testing and magnetic particle testing - Viewing conditions

- ISO 9934-1: Non-destructive testing - Magnetic particle testing - Part 1: General principles

- ISO 9934-2: Non-destructive testing - Magnetic particle testing - Part 2: Detection media

- ISO 9934-3: Non-destructive testing - Magnetic particle testing - Part 3: Equipment

- ISO 10893-5: Non-destructive testing of steel tubes

- ISO 17638: Non-destructive testing of welds - Magnetic particle testing

- ISO 23278: Non-destructive testing of welds - Magnetic particle testing of welds - Acceptance levels

CEN (European Committee for Standardization)

- EN 1290: Surface Crack Testing

- EN 1330-7: Non-destructive testing - Terminology - Part 7: Terms used in magnetic particle testing

- EN 1369: Founding - Magnetic particle inspection

- EN 10228-1: Non-destructive testing of steel forgings - Part 1: Magnetic particle inspection

- EN 10246-12: Non-destructive testing of steel tubes - Part 12: Magnetic particle inspection of seamless and welded ferromagnetic steel tubes for the detection of surface imperfections

- EN 10246-18: Non-destructive testing of steel tubes - Part 18: Magnetic particle inspection of the tube ends of seamless and welded ferromagnetic steel tubes for the detection of laminar imperfections

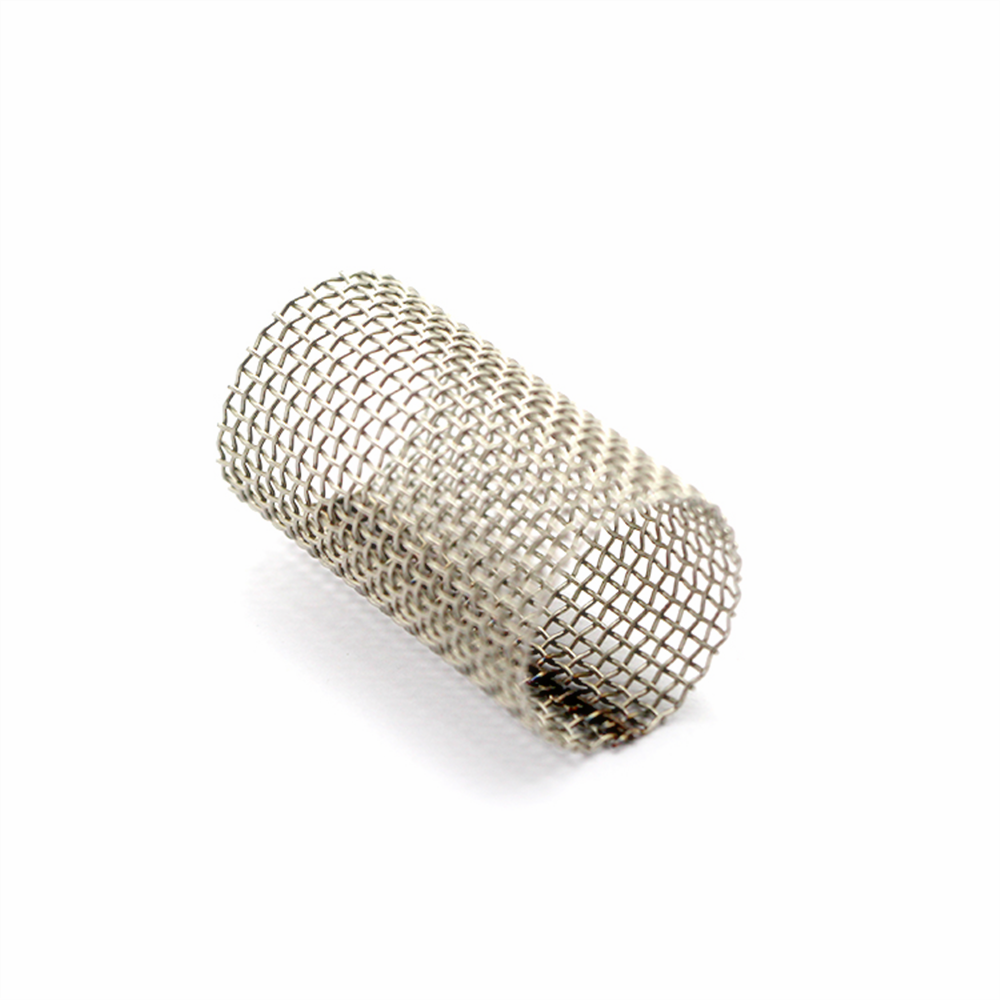

Wire mesh cylinder filter also called Wire Mesh Filter Tube ,metal mesh filter tube ,woven wire mesh tube and so on.The wire mesh cylinder filter is made of Stainless Steel Wire Mesh ,galvanized Welded Wire Mesh ,metal perforated sheet, iron wire mesh etc.

Â

Material :SS 201.202.302.304.306.316.316L.Among them,304 316 316L are most commonly used.

Production Process: after cutting, bending, stamping, rolling, welding, polishing and other procedures of production.

Features for wire mesh cylinder filter: good straightness, stainless steel material, heat resistance, corrosion resistance, long service life.Â

Â

Application :

1) Catalyst filtration and separation; Â

2) petrochemical high temperature gas filtration, petrochemical plant boiling bed exhaust filtration, catalytic cracking slurry filtration; Â

3) Purification of high-temperature flue gas in metallurgical industry; Â

4) Filtration of other high-temperature gases and liquids; Â

5) Filtration of high temperature, corrosive liquid and catalyst in petrochemical industry;Â

6) Filtration and purification of various polymer melts in chemical fiber film industry; Â

7) Filtration and separation of various catalysts in pharmaceutical industry; Â

8) For gas distribution, liquid bed hole plate material; Â

9) Used for high pressure backwash oil filter, etc.; Â

10) Various grout for filtering edible oil, beverage and food; Â

11) Used to purify and filter production sewage.Â

Â

Â

SS304 Cylinder Filter Tube,Woven Mesh Screen Tube ,Metal Mesh Cylinder Filter

Suzhou Haoxiang Screen Stencil Products Co.,Ltd , https://www.haoxiangwiremesh.com