Light Emitting Diodes (LEDs) have completely transformed the lighting industry. Compared to traditional lighting sources like incandescent and fluorescent bulbs, LEDs offer superior energy efficiency, better light quality, and a significantly longer lifespan. These advantages have led to their widespread adoption across various industries. According to the U.S. Department of Energy, LEDs accounted for 48% of installed lighting units in 2020, up from just 8% in 2015 and 1% in 2010.

As LED technology has advanced, so has the competition among manufacturers. The race to produce brighter and more efficient fixtures has led to some questionable practices when it comes to how performance is measured and presented. One common tactic is to test only the bare LED chip rather than the complete fixture, including lenses and other optical components. This can create misleadingly high efficacy numbers that don’t reflect real-world performance.

In this article, we’ll explore what luminous efficacy really means, why it matters in solar lighting, how some manufacturers misrepresent their products, and how you can identify reliable, high-quality LED fixtures.

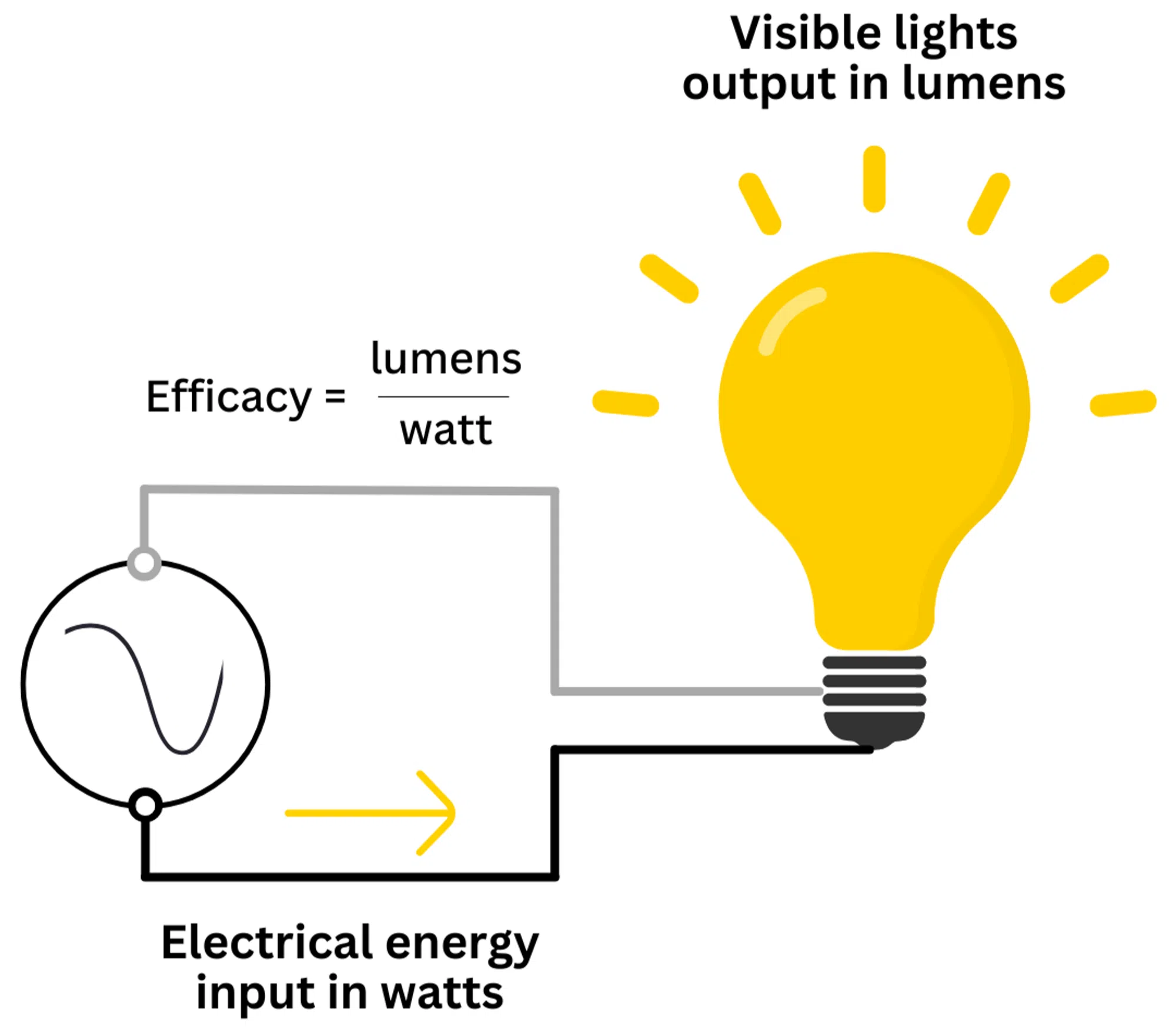

What is Luminous Efficacy?

The Illuminating Engineering Society (IES) defines luminous efficacy as “the total emitted luminous flux divided by the total source electrical input power.†It is typically expressed in lumens per watt (Lm/W or LPW) and measures how effectively a light source converts electrical energy into visible light. For example, a fixture that emits 1500 lumens using 20 watts would have an efficacy of 75 LPW. If another fixture emits 2500 lumens at the same 20 watts, its efficacy would be 125 LPW—significantly higher because it produces more light with the same power.

While efficacy is a key metric for comparing fixtures, it’s often confused with "efficiency." However, they are distinct concepts. Efficacy refers to the amount of visible light produced relative to the power consumed, while efficiency relates to how much of that light is actually delivered to the desired area. In short, efficacy is the more useful measure for evaluating lighting performance.

Why Does Efficacy Matter for Solar Lighting?

For grid-connected systems, higher efficacy means lower energy costs and reduced strain on the power grid. But for solar-powered lighting, where energy is free and abundant, does efficacy still matter? The answer is yes—but for different reasons.

A higher-efficacy fixture requires less power to produce the same amount of light. This means smaller solar panels and batteries, which leads to more affordable and compact systems. It also allows for easier installation in remote or high-latitude areas where sunlight is limited. Additionally, lower power consumption reduces the overall footprint of the system, making it a more sustainable and cost-effective solution.

How Do Manufacturers Mislead with Efficacy?

To stand out in a competitive market, some manufacturers test only the LED chip without considering the full fixture, such as lenses and drivers. This results in inflated efficacy numbers that don’t reflect real-world performance. While these numbers may look impressive on paper, they are not representative of how the product will perform once installed.

This lack of transparency makes it difficult for buyers to compare products fairly. To avoid being misled, it's important to ask questions about testing methods and whether the efficacy values are based on the entire fixture or just the LED component.

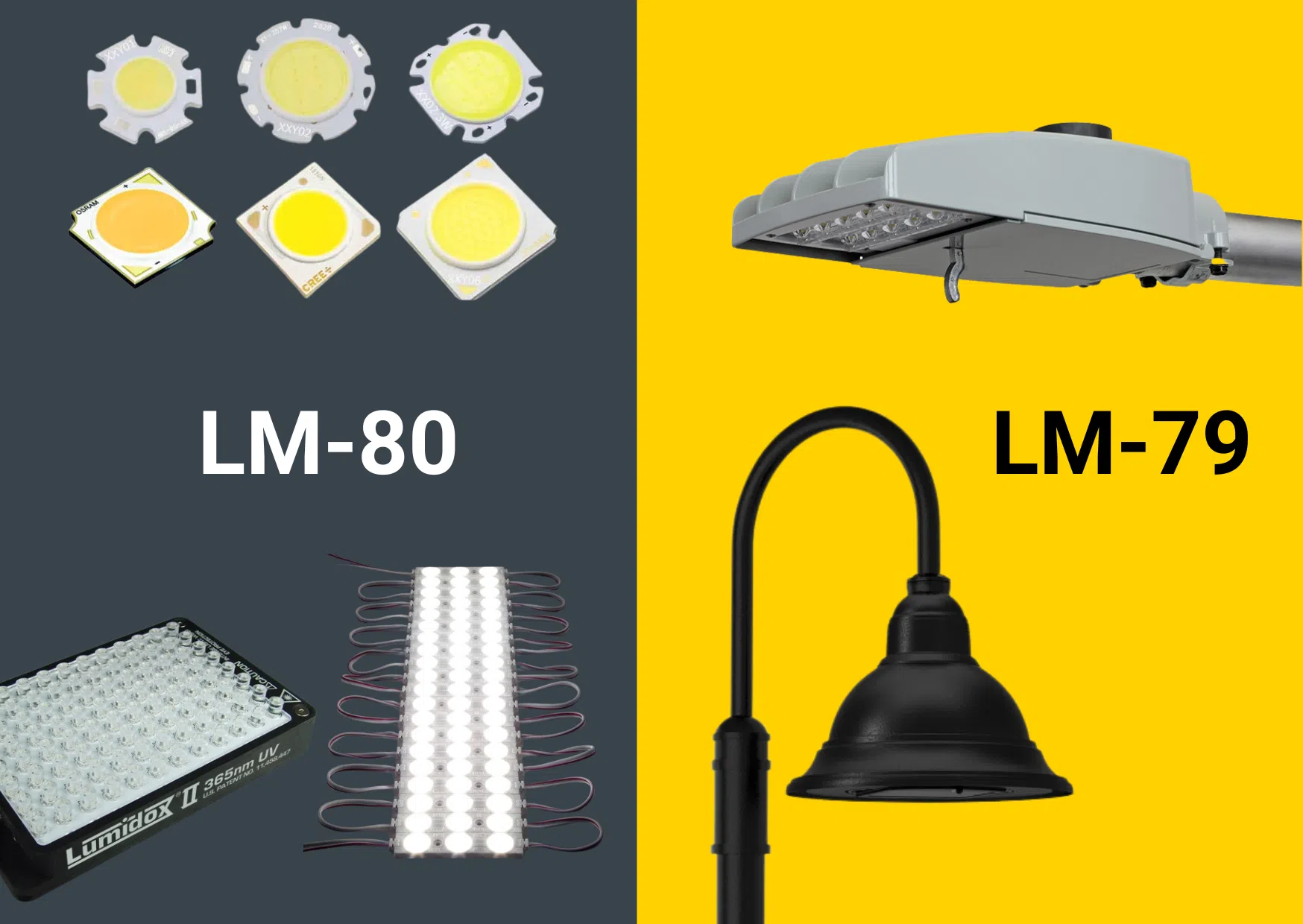

The Importance of LM-79 Testing

One of the most reliable ways to verify a fixture’s true performance is through LM-79 testing. This IES-approved standard measures the optical and electrical characteristics of solid-state lighting products, including luminous flux, intensity, and efficacy. Unlike other tests, LM-79 is performed on the complete fixture, ensuring accurate and comparable data between manufacturers.

When evaluating a product, always check if it has undergone LM-79 testing. You can usually find this information on the manufacturer’s website or in technical documentation. If not, don’t hesitate to ask the manufacturer directly.

Other Red Flags to Watch For

Other signs of questionable efficacy claims include numbers that fall outside the typical range for reputable manufacturers. Most high-quality fixtures have efficacies between 120–160 LPW. If a product claims significantly higher or lower values, it’s worth investigating further. Also, watch out for fixtures that maintain the same efficacy at different power levels—this is unusual and could indicate misleading data.

Making Informed Purchase Decisions

Understanding luminous efficacy and knowing how to interpret it is essential when choosing a lighting system. While not all manufacturers use the same testing methods, independent standards like LM-79 help ensure consistency and reliability. When in doubt, ask the right questions and request detailed test reports.

If you're unsure about a product’s performance, here are some questions you can ask:

- Can you provide independent testing results for your efficacy claims?

- How do you measure lumens in your products?

- What is the total fixture efficacy, including drivers and lenses?

- Can you provide photometric reports for the fixtures?

- Are your efficacy claims based on initial or maintained lumens?

- Do you have references or case studies of similar installations?

Have a question about efficacy or anything else related to solar lighting? Our team of experts is here to help. Contact us today!

Welding Recondition is the best way to reduce cost through increase working life of your equipment. Take Vertical Roll Mill for example, the Coal Vertical Roll Mill (VRM) is an air scanning, medium speed vertical mill with an integrated classifier. It pulverizes coal by applying a hydraulically loaded grinding pressure through three grinding rolls to a rotating bed of coal. The grinding pressure can be adjusted to take into account changes in coal grindability and desired product fineness.

Working principle

The raw material is uniformly fed through the feeder at the bottom of the hopper, and then raised to a suitable height by the bucket elevator, and then sent to the mill through the feeding pipe for grinding, and the ground material enters the powder classifier and is produced by the hot air furnace. Hot air, at the same time dry and grade the material, the unqualified material is poured into the grinding, the qualified fine powder is sent to the powder collector, and then transported to storage. Through the conveyor.

Application

Can be widely used in cement, power, metallurgy, chemical, non-metallic minerals and other industries. It is used to grind granular and powdered materials into powders with the required fineness.

Introduction

It can cover the grinding machine table of various sizes and styles. We can rebuild the table internally or on site according to your needs. We also offer cast steel table replacement and a suitable overlapping section to ensure fit.

Feature

* Longer use time and lower maintenance costs

*Optimal production efficiency

*save costs

*customized product

* Environmental protection

Our service

We specialize in custom high temperature wear resistant products to improve the service life of various mechanical settings.

We are committed to customer satisfaction and high performance. We insist on providing the highest precision at the most fair price with quality products and providing the best service to all our customers.

Welding Recondition On Spare Parts Of Vertical Mill,Welding Recondition On Hammer, Welding Recondition On PickupWelding Recondition On Roller Press

HuiFeng Wear Resistant Group , https://www.hpwearsolution.com