The rice rate of polished rice in the national standard GB1350-1999 is as follows: When the rice is milled using a rice grinder to the first grade of the national standard, the rice grains are broken, and the length is still five times the average length of the complete polished rice. Four or more (four-fifths) of the grains accounted for the percentage of net rice samples. Since then, the national standard GB1350-2009 has not only revised the length requirement of the whole polished rice grain. The length of the revised whole polished rice grain is defined as three quarters of the average length of the whole grain, and the grading standard for the rate of whole polished rice in the glutinous rice and japonica rice is performed. Refined and stipulated that the rate of whole polished rice was divided into 5 grades (1-5 grades), among which, indica rice grains were: ≥50%, ≥47%, ≥44%, ≥41%, ≥38%; For: ≥ 61%, ≥ 58%, ≥ 55%, ≥ 52%, ≥ 49%, and the differential level is 3%. The grading standard for the rate of polished rice in indica rice was more refined in NY/T 593-2002 of the Ministry of Agriculture, and the indica rice varieties were classified in detail according to the grain type (1-5, etc.) and long-grained (>6.5 mm). ) The percentage rate of whole polished rice is: ≥50%, ≥45%, ≥40%, ≥35%, ≥30%; the rate of whole polished rice in middle grain type (5.6~6.5mm) is graded as: ≥55%, ≥50 %, ≥45%, ≥40%, ≥35%; Short-grained (<5.6 mm) varieties were graded as: ≥60%, ≥55%, ≥50%, ≥45%, ≥40%, grade difference They are all 5 percentage points. Indica rice grading is: ≥72%, ≥69%, ≥66%, ≥63%, ≥60%, with a difference of 3%. Since the rate of whole polished rice directly reflects the appearance quality, processing quality, and commodity economic value of rice, the quality standards of rice have used the whole polished rice rate as a separate inspection item and used it as an indicator to assess the level of rice or as a limitation. Sexual indicators, which are very important for guiding the cultivation of rice, adjusting and optimizing the structure of varieties and the acquisition and management of rice.

The rate of polished rice in rice varieties is not only directly related to the product rate after rice processing, but also has a direct relationship with the pros and cons of the varieties themselves. In general, rice grains are large in size, with fewer keratin plasmids, loose starch grains, and whole grains. The rate is relatively low. On the contrary, the white rice grains are small in abdomen or white, there are many horny plasmids, and the starch grains are tightly packed. The rate of whole polished rice is higher. Long-term practice has proved that the quality of inferior varieties and high-quality varieties in the same type of rice varies greatly, and the rate of whole polished rice varies greatly. In addition, the cooking characteristics of different rice varieties with the same finishing rate and the texture characteristics of whole grains and crushed grains in rice were also tested. The results showed that: the whole rice has better eating quality than crushed rice; The hardness and adhesion force are less than the hardness and adhesion of the whole grain. For the rice of the same variety, the higher the rate of whole rice production, the better the edible quality of the rice.

In general, the ratio of polished rice to japonica rice is higher than that of japonica rice. Therefore, it is particularly important to increase the rate of polished rice in slender japonica rice varieties. Because the rate of japonica rice is closely related to the variety itself, the choice of varieties is to increase rice. The basis of the rate of whole polished rice, therefore, how to quickly and accurately discriminate the rate of whole polished rice of japonica rice has become a key issue for the selection of japonica rice varieties. In this study, 13 different grain type early-season rice cultivars were selected. After harvesting, they were exposed to sunlight for 36 h, indoor air-dried for 1 month, and oven gradient temperature and time treatment. The rate of whole polished rice of various treatments was counted. Accurately identifying the rate of whole polished rice of japonica rice varieties was tested. Due to the different drying methods adopted after the daily rice varieties are harvested, even if the same variety is used, the rate of whole polished rice is often very different, which makes the value of whole polished rice rate lose its reference value.

Therefore, this experiment specifically selected two relatively extreme treatment methods, namely exposure and indoor natural air drying. The rate of whole milled rice processed by these two methods represents the lower and higher levels of two types of whole polished rice and can reflect the varieties themselves. The level of polished rice rate has guiding significance for the selection of varieties.

The oven is equipped with gradient temperature and time processing. The purpose is to find out in which temperature conditions the drying time can be matched with the rate of exposure and indoor air-drying, and the right temperature and time points can be found directly. Fresh rice seeds are placed in an oven and baked at a specific temperature for a specific time to determine the percentage of polished rice. Compared with the traditional method of determination, there is no need to wait for the number of days of exposure or how long it takes to dry, which greatly saves time, enables rapid identification of the rate of whole polished rice of japonica rice varieties, and improves the selection efficiency of varieties.

Related Products: Starch Tester

The main material of the product is carbon steel.

The handle of the product is telescopic.

The design of the handle is hard and light.

Packing: Ratchet Cable Cutterpacked by carton or as your request.

Applications: Electric power industry,Mommunication industry,Mhip-building industry,Metaluraical industry.

Features:

1. Cutting easily with forging blade and long lifetime

2. Not for cutting steel or steel wire

3. With safety lock

4. Cutting Range:240mm² max.

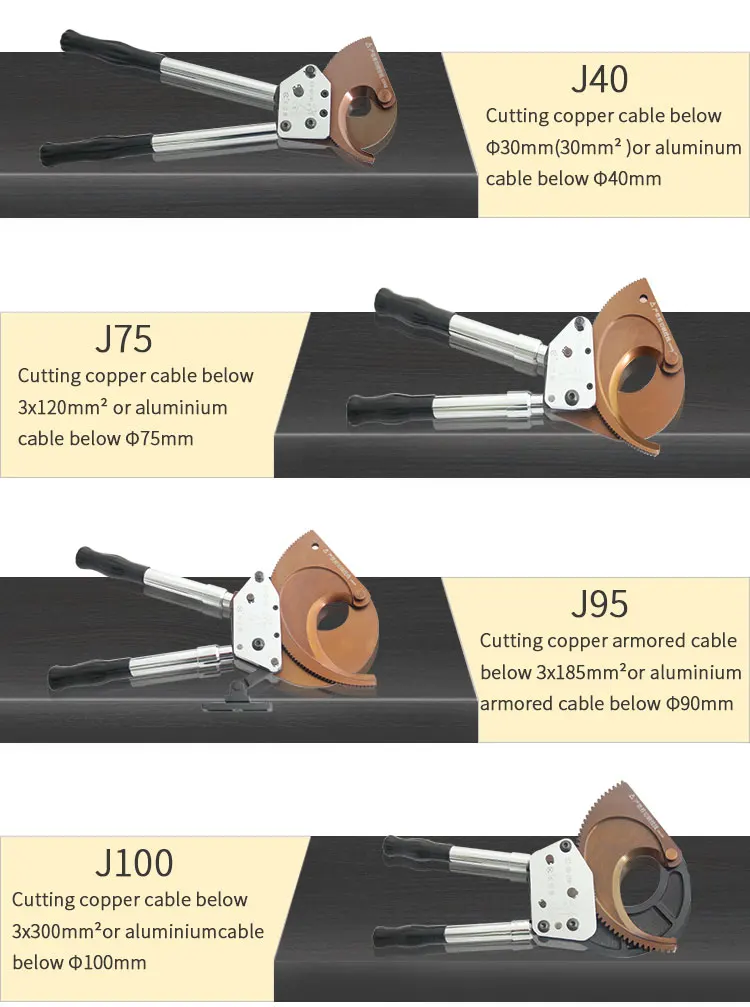

Ratchet Cable Cutter Different specifications as below:

|

Ratchet cable cutter |

||

|

Model |

Size |

Weight |

|

J12 |

345(514)*125*46mm |

1.95kg |

|

J30 |

405(514)*160*64mm |

3.6kg |

|

J13 |

345(514)*125*46mm |

1.95kg |

|

J25 |

745*135*50mm |

3.45kg |

|

J50 |

400(570)*158*52mm |

3.2kg |

|

J40 |

260*100*35mm |

1.15kg |

|

J40A |

245*135*42mm |

1.05kg |

|

J40B |

250*95*30mm |

0.65kg |

|

J75 |

420*205*50mm |

3.6kg |

|

J95 |

818*265*50mm |

5.43kg |

|

J100 |

490*270*50mm |

6.4kg |

|

J130 |

500*300*50mm |

8.1kg |

|

J160 |

500*300*50mm |

8.11kg |

Ratchet Cable Cutter Details:

Ratchet Cable Cutter

Ratchet Cable Cutter,Cable Cutters,Ratchet Cutters,Ratchet Wire Cutters

Hebei Long Zhuo Trade Co., Ltd. , http://www.hblongzhuo.com